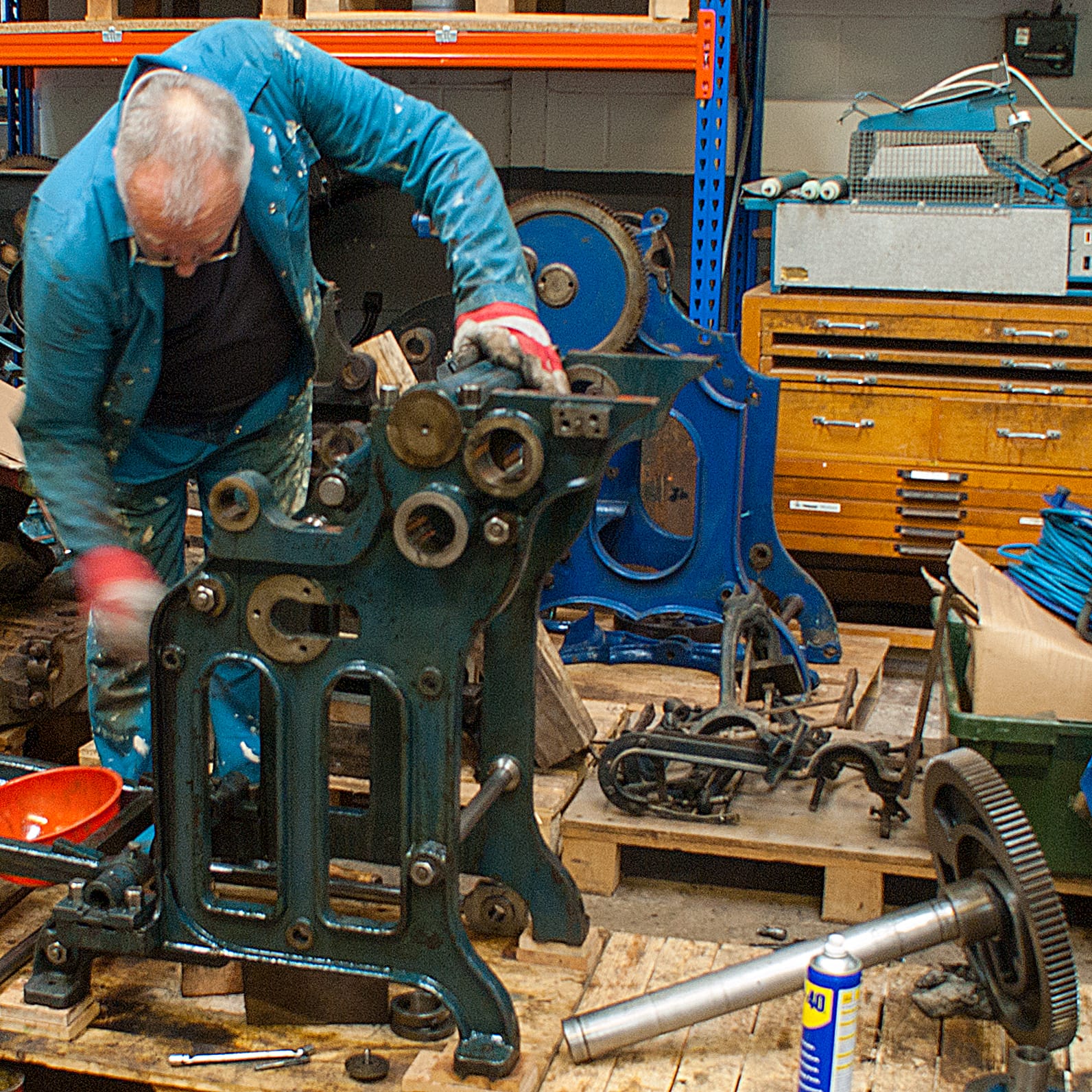

AFTER checking the operation and for any faults, the machine to be restored is completely dismantled in order to start the rust removal and degreasing processes. Bright metal surfaces are polished and unfinished cast surfaces are treated against rust and then painted or have a traditional black paste applied and buffed to a satin finish.

IF any bearings or parts need to be cast, usually in bronze or iron, then patterns are made and taken to one of the foundries used by Josiah Wade Limited. Bronze bearings are turned to the correct size in the lathe and surfaces of parts milled, drilled, tapped, etc. on the milling machine. New roller runners and stocks are made and covered with rubber of the correct hardness. Presses with leather bearers have new ones fitted.

THE finishing touch to many restorations is the addition of new wooden handles on an Albion or Columbian, new wooden tables on treadle platens and two oiled hardwood battens on which to stand the press. These are made in a variety of woods in keeping with the age and origin of the press.